Laser manufacturing in the pharmaceutical industry

Technological progress thanks to laser technology

Pharmaceutical products are literally necessary for survival in our society. The market and the legislators impose ever more complex requirements on drug manufacturers. Laser technology allows us to produce components of filter systems, powder mixing systems or agitators to satisfy particularly high quality demands and quantity demands.

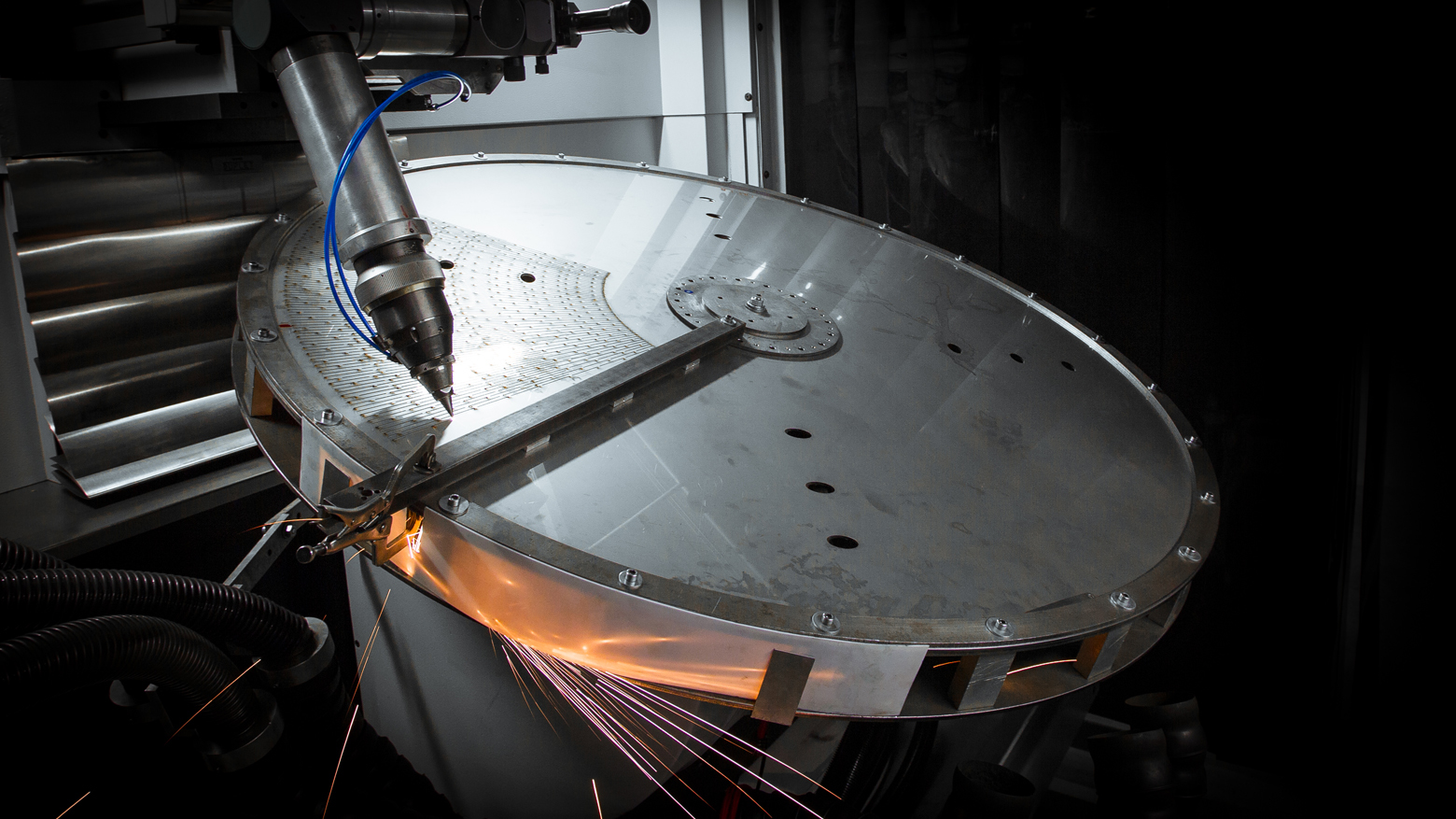

Tablets are dusted with powder in a fluidized bed system to protect them against moisture. High-quality laser-machined stainless steel discs - called diskjets - are used for this. A fluidized bed is generated by the diskjet distribution base. Air that is fed in distributes the powder evenly through a base spray system on to tablets lying in a drum.

Such distribution bases have diameters up to 2 metres. We laser cut these on specially manufactured jigs. So as to satisfy the hygiene requirements of the pharmaceutical industry we clean, polish and pickle the products before we deliver them.

Laser applications enable the manufacture of technologically advanced fluidized mixing systems. They are more efficient and have greater process reliability than ever.